How To Properly Inspect Exhaust Manifolds

We are constantly reading & researching the latest information on all things marine as it relates to our business.

We recently came across this article in Boating Magazine , written by Mick Hannock. It is informative, worth sharing & worth your time reading.

Tips for Inspecting Exhaust Risers and Manifolds

Inspection tips that might help you prevent an engine catastrophe.

Iron castings, such as exhaust manifolds and risers, fail from corrosion as they cool and contract. Many a boat that runs well has been put in its slip on Saturday afternoon only to have water siphon from corrosion-damaged castings into the cylinders overnight. Upon Sunday’s start-up, incompressible water does irreparable engine damage. These inspection tips might help you prevent catastrophe.

Manifold

With raw-water-cooled engines used in salt water, you might expect their manifolds to have a three- to five-year life. Corrosion may warrant replacement in 10 years if an engine used in salt water has a closed cooling system.

Riser

Check risers and elbows starting at two years, and annually thereafter, if the boat is used in salt water. Even with a closed cooling system, the risers are raw-water cooled. Risers usually fail before manifolds do.

Fresh Perspective

Risers and manifolds used in fresh water have an almost indefinite life. Keeping an eye on the gaskets and checking the bolts for proper torque annually still makes good sense.

Clean Machine?

Clogged manifolds can be acid-cleaned and pressure-checked. Just remember that a “thumbs up” today is no guarantee against corrosion failure occurring without warning tomorrow. What’s your engine worth?

Gat-get?

Rust stains emanating from the riser-manifold joint mean the gasket is failing, the riser is loose or the mating surfaces have started to corrode. Look for these before every outing.

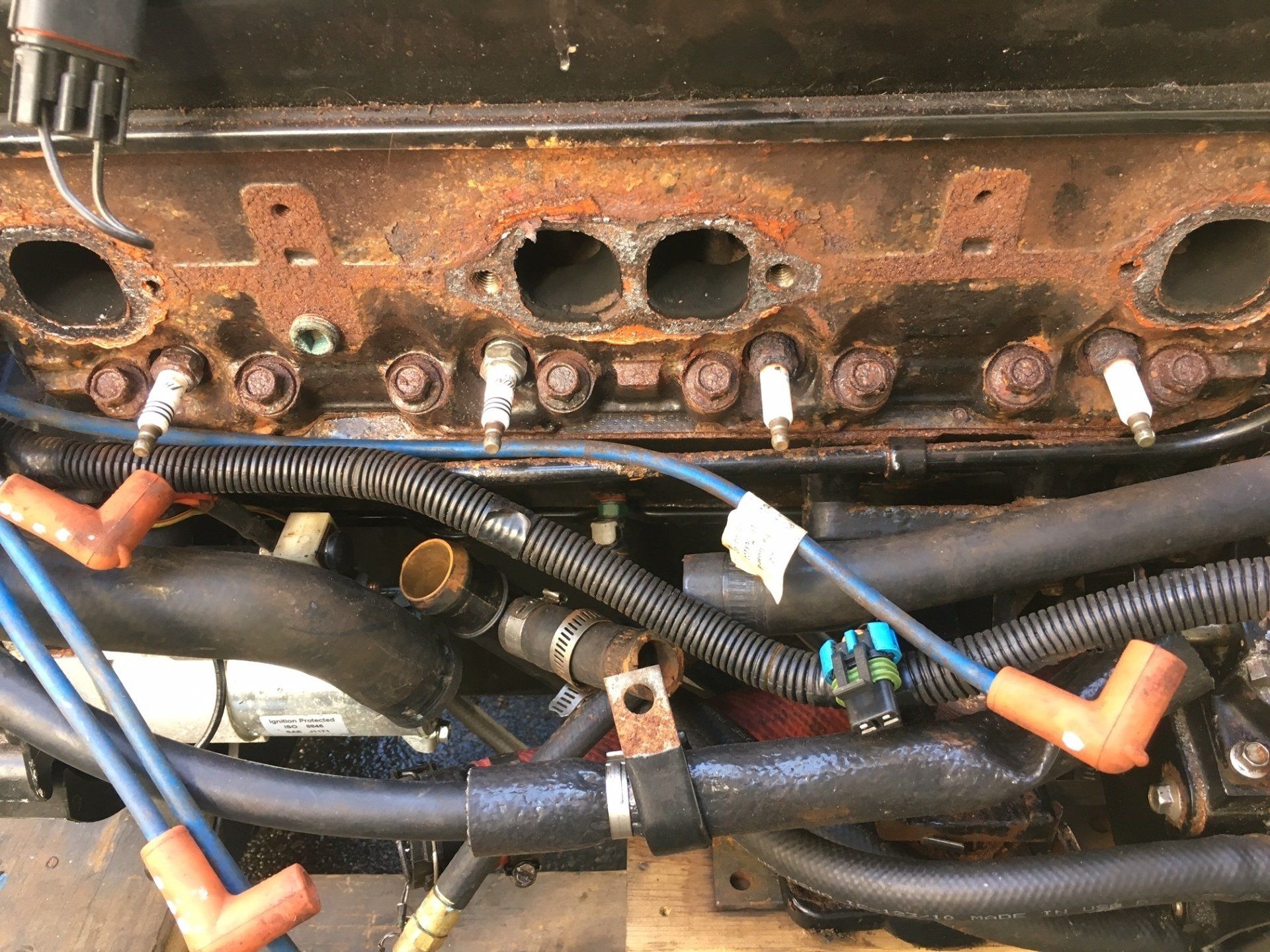

Drain ’n’ Pull

Drain the water from your engine’s risers and manifolds in order to perform a visual inspection. Unclamp the exhaust hoses. Remove the bolts securing the risers and/or elbows and look inside.

Poke ’n’ Look

Heavy corrosion or material dislodged by reaming with an old flat-head screwdriver or other tool warrants replacement. Check mating surfaces for flatness with a straightedge. Look for cracks.

New, New

Use new gaskets, whether reinstalling your old risers or replacing them with new ones. Old gaskets may be fine, but new ones are cheap compared to the time needed to dismantle these parts again.

Hand, Eye

With the risers off you can see into the manifolds a little. Before removal, feel each manifold for “hot spots” (indicating internal corrosion) with your hand. Pros use a tool called an infrared pyrometer to diagnose manifolds.

Quick Tip

Secure disconnected exhaust hoses above the waterline to prevent sinking your boat!

Give us a call us today for more information at

(604) 921-7124. We’d be happy to talk with you.